Get your game on with our courts and flooring options.

We have the best price-to-performance ratio on the market, FlexCourt® wants your family to truly enjoy the rewards of having your own high-performance indoor or outdoor court.

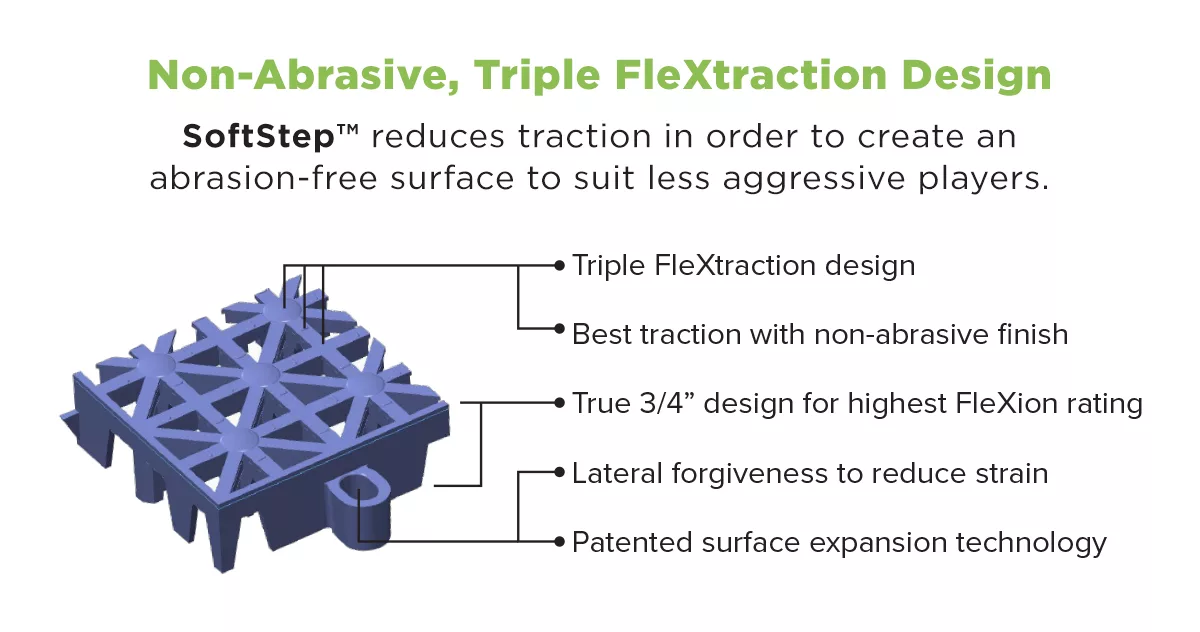

Patented FlexLock™ design offers a virtually seamless surface with the best shock absorption and FleXion™ rating in the industry and the best TraXion™ tested surface. It offers the best surface performance for every climate condition. Be it wind, rain, heat, ice or snow, our outdoor courts and indoor floors are built to last. They drain extremely well so even if you experience inclement weather, you’ll be back playing fast. FlexCourt® is also engineered so that the understructure provides superior shock absorption and added safety during play.

What are the FlexCourt Outdoor court options?

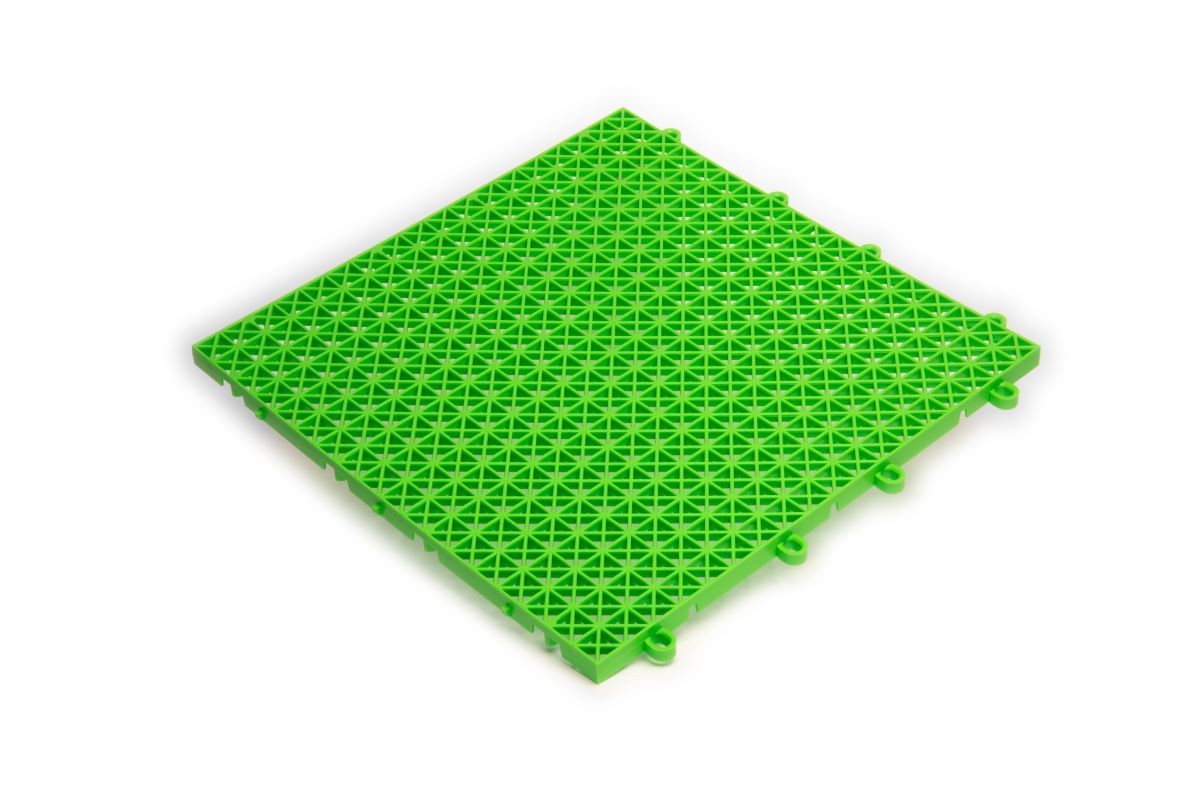

FlexCourt® outdoor courts help you extend your playtime and comfort by eliminating much of the jarring impact inherent in hard surface courts. All three options bring you the ultimate level of sports performance for basketball, volleyball, tennis, hockey, and more.

Take your pickleball game outdoors with EliteStep™, the largest, most joint-forgiving tile on the market from FlexCourt®. These brand-new outdoor tiles are 40% larger than our competitors’, making them the largest in the industry with superior bounce and rebound! Plus, our specially engineered texture offers enhanced traction, playability, and reduced stress on joints — extend your playing time with unparalleled horizontal and lateral forgiveness! EliteStep™ includes a market-leading UV resistance package and drains quickly, making it perfect for all seasons with little to no maintenance.

What are the FlexCourt Indoor floor options?

FIexCourt Indoor floors are also safe on your joints. Indoor floors are installed over a 2mm, 3mm, or 4mm rubber pad that immediately creates vertical forgiveness to help reduce strain on joints. Our Indoor floor options with FleXshield™ coating are extremely scratch and scuff resistant, tougher than most, have a longer life cycle and cannot be damaged by moisture or water.

Does FlexCourt offer accessories and components?

FlexCourt® offers a full line of court components with standard and custom options for residential, multi-game and commercial installations. These include residential basketball goals, multi-game net systems and rebounders, commercial court lighting, and indoor basketball goals.